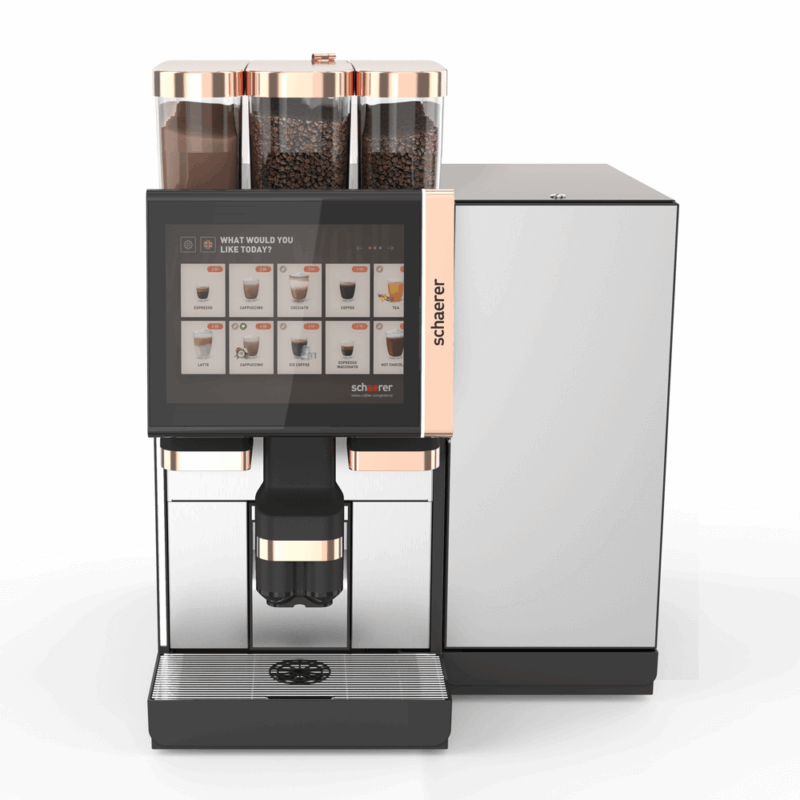

PSSR Inspections for Commercial Coffee Machines

Stay compliant and protect your team with a professional PSSR inspection for your commercial coffee machine. Our IOSH-certified engineers deliver thorough checks to ensure your steam boiler is safe, functional and operating within the legal Pressure Systems Safety Regulations (2000).

Reliable Service

Remote Technical Support

Get expert help fast; our team aim to resolve most issues remotely within 30 minutes over the phone.

Nationwide Service

With one of the UK’s largest in-house coffee engineer teams, we’re always there when you need us.

24/7 Account Access

Manage orders, book servicing and access support videos anytime with My Account.

Thorough Safety Inspection

If you have a commercial coffee machine that uses pressurised steam, then it’s essential that you have a PSSR (Pressure Systems Safety Regulations) check carried out regularly. The PSSR inspection includes a thorough safety inspection of the pressurised vessel and valves to ensure your commercial coffee machine is in tip top condition and is safe to use.

Liquidline’s experienced, fully trained Engineers can carry out a PSSR inspection on a Liquidline-supplied machine, as well as those provided by other suppliers, completing a fully comprehensive service and providing you with an IOSH certificate.

Why do I Need a PSSR Check?

A PSSR Inspection ensures that you are meeting your legal obligation to comply with the Pressure Systems Safety Regulations (2000) and also protects your visitors and team from accidents that can occur when machines are left unmaintained. Failure to have your machine PSSR checked regularly may also invalidate your liability insurance.

Book Your PSSR Inspection

Book a PSSR inspection with one of our expert engineers today to ensure your machine is compliant, safe and running efficiently. We cover both Liquidline and third-party commercial coffee machines.

Types of Coffee Machines We Inspect

Our team of trained IOSH-certified Engineers can carry out a PSSR inspection on all our own machines, as well as those supplied by other companies.

If your make or model of coffee machine isn’t in the list, please get in touch with our team and we’ll be happy to advise.

Related Insights

Enquire Today

Please complete the form, and we’ll be in touch shortly. Alternatively, please call Liquidline on:

An IOSH-certified Engineer will visit your premises to carry out a full pressure test of the steam boiler safety valve and inspect the boiler vessel inside and out. The machine is stripped down, the boiler drained, and the heating element removed for inspection. After reassembly, it is tested at full pressure. An IOSH certificate is issued on completion, with internal images available if required.

Under the terms of the Pressure Systems Safety Regulations (2000), you have a statutory duty to have your commercial coffee machine inspected once it is over 14 months old. After this, we advise having your machine checked every 12 months or so, though this does vary depending on the type of machine and frequency of use.

Not all commercial coffee machines require a PSSR check, only machines that use a pressurised vessel, such as Bean to Cup and Traditional Espresso Machines, require regular PSSR testing. Most filter coffee machines for example do not require a PSSR inspection, though we still recommend regular maintenance to prolong the life of the machine and ensure it’s safe for your team to use.

"*" indicates required fields

Frequently Asked Questions

An IOSH-certified Engineer will visit your premises to carry out a full pressure test of the steam boiler safety valve and inspect the boiler vessel inside and out. The machine is stripped down, the boiler drained, and the heating element removed for inspection. After reassembly, it is tested at full pressure. An IOSH certificate is issued on completion, with internal images available if required.

Under the terms of the Pressure Systems Safety Regulations (2000), you have a statutory duty to have your commercial coffee machine inspected once it is over 14 months old. After this, we advise having your machine checked every 12 months or so, though this does vary depending on the type of machine and frequency of use.

Not all commercial coffee machines require a PSSR check, only machines that use a pressurised vessel, such as Bean to Cup and Traditional Espresso Machines, require regular PSSR testing. Most filter coffee machines for example do not require a PSSR inspection, though we still recommend regular maintenance to prolong the life of the machine and ensure it’s safe for your team to use.