We all know the feeling; sitting in traffic or on a packed train or bus, travelling to work. We arrive, often exasperated before the day has even begun. We know that there is just one thing powerful enough to turn the day around. And the feeling that washes over you when you take the first sip of coffee- we call that feeling Café Bonté. We understand that not all Café Bonté experiences take place in the coffee shop. Our mission is to bring great coffee and good feelings to people everywhere that coffee is enjoyed. Great coffee has the potential to make people feel good and to connect; with the place they are visiting, the purchase they are about to make or the person they are with. We believe that we all deserve Café Bonte moments and we strive to bring them to as many people as possible. We start by sourcing Grade A quality coffee beans from around the world.

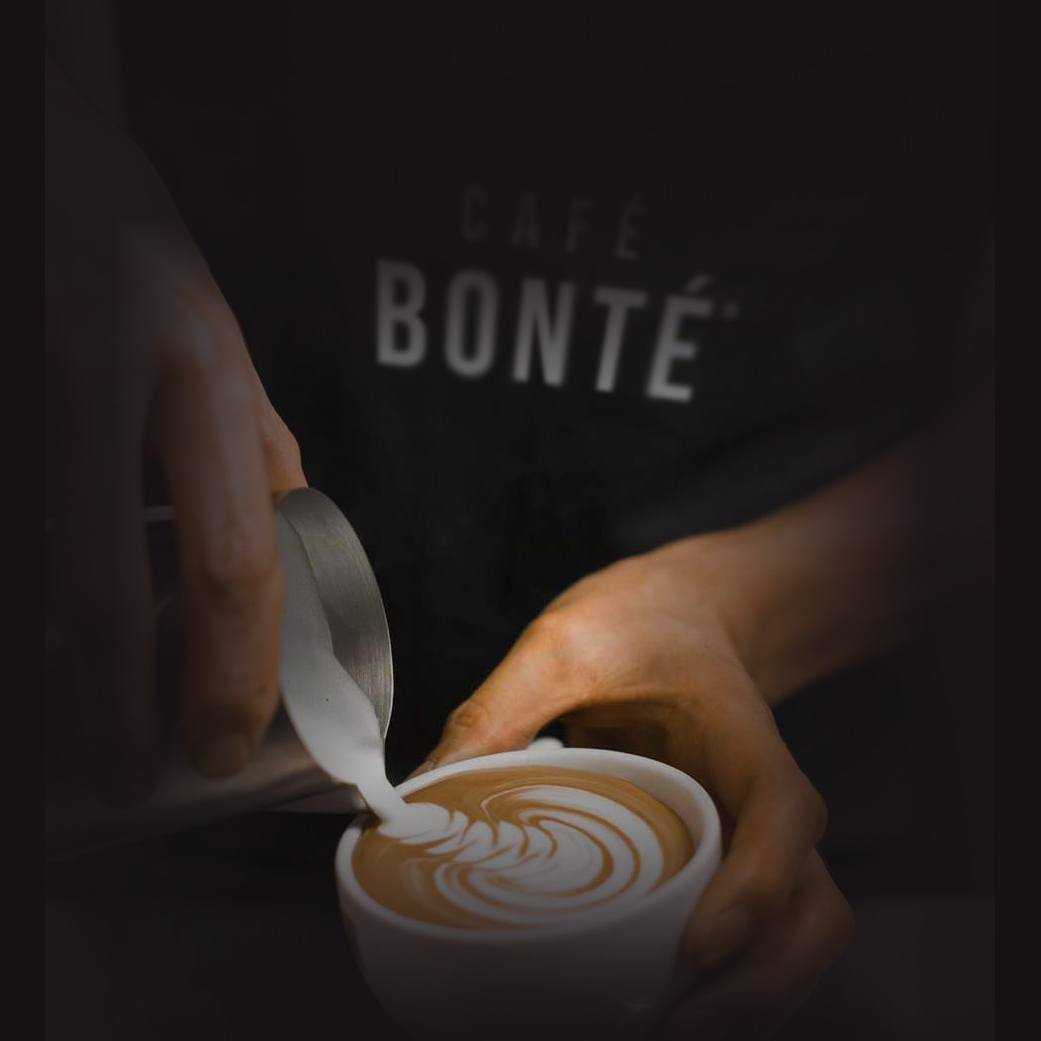

The Café Bonté Story

We employ all of our years of knowledge and expertise, expertly roasting the beans to satisfy the diverse tastes of today’s UK coffee lovers. We understand how personal coffee is and we have carefully curated our range to deliver perfect Café Bonté moments for every taste and preference. We also understand that to truly feel good about the coffee you’re drinking, it can be important to know where it comes from. With this in mind, you will find a full complement of ethical certifications within our range as well as triple certified and fully closed loop coffee beans. We are dedicated to bringing the Café Bonté feeling to as many people as possible and thousands of people across the UK already start their day with Café Bonté. We understand that not everyone is a coffee connoisseur but passionately believe that we all deserve great coffee and good feelings, wherever we are.

Great Tasting Coffee

We offer many different varieties of our Café Bonté ground coffee that are suited to fit your needs as a consumer. If you prefer a rich roast coffee then try our Café Bonté Panorama Bulk Brew Coffee roast, available packet ready. All our coffee is graded depending on strength, with the option to purchase decaf. Enjoy freshly ground, filter coffee that is high in quality and guaranteed to impress.

Marketing

Create a customer experience with Café Bonté point-of-sale. Encourage your customers with loyalty cards, menus and make them visible at all times.ng the Wayfinding app

Our Equipment

We have a huge range of consumables from in-cup drinks to machine filters and parts, as well as capsule coffee machines available for purchase, lease and rental. Customise your own branded coffee pods and crockery, and wall menus.

Barista Competitions

Café Bonté was first introduced at the 2015. Lee Corke, Chairman of the Cambridge Culinary competition Committee claimed that the event was “bigger and better than ever” this year.

The Café Bonté brand has since evolved and the Barista competition has now become a worldwide success and very popular in the coffee industry.

Explore all our brands

Most people know us through our brands. Our portfolio covers almost every consumable and beverage equipment category – offering products and services for all every type of business, every moment of the day, helping businesses care for customers, staff and themselves. Here is a sample of some of our brands. For more information, visit our Brands section.